KPX

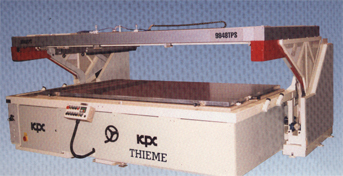

2000T / TK400 SEMI-AUTOMATIC WITH "TAKE OFF" OPTION KPX

2000T / TK400 SEMI-AUTOMATIC WITH "TAKE OFF" OPTION |

| |

|

|

•

The patented Thieme High Tech Squeegee System •

The patented Thieme High Tech Squeegee System |

•

From screen frame loading •

From screen frame loading |

•

Upgrade, movable central pause •

Upgrade, movable central pause |

•

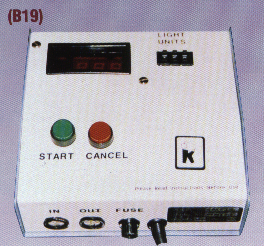

Digital display of important operation functions •

Digital display of important operation functions |

•

Effortless insertion and removable of squeegees and •

Effortless insertion and removable of squeegees and |

floodcoaters floodcoaters |

•

Individual command of all press movement •

Individual command of all press movement |

| |

•

Programmable stroke length •

Programmable stroke length |

| |

•

Foot pedal cycle operation with pre-vacuum integration •

Foot pedal cycle operation with pre-vacuum integration |

| |

|

•

And many more •

And many more |

| |

|

|

| |

|

(For

additional information, please refer to the brochure) (For

additional information, please refer to the brochure) |

| |

|

|

| |

|

|